| Sign In | Join Free | My fazendomedia.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My fazendomedia.com |

|

Place of Origin : Shanghai, China (Mainland)

Brand Name : Xinye

Model Number : Injection Mould

Price : negotiable

MOQ : 1 Pair/Pairs

Shaping Mode : Plastic Injection Mould

Product Material : Steel

Product : elevator parts mould

Product Name : Plastic Injection Mould

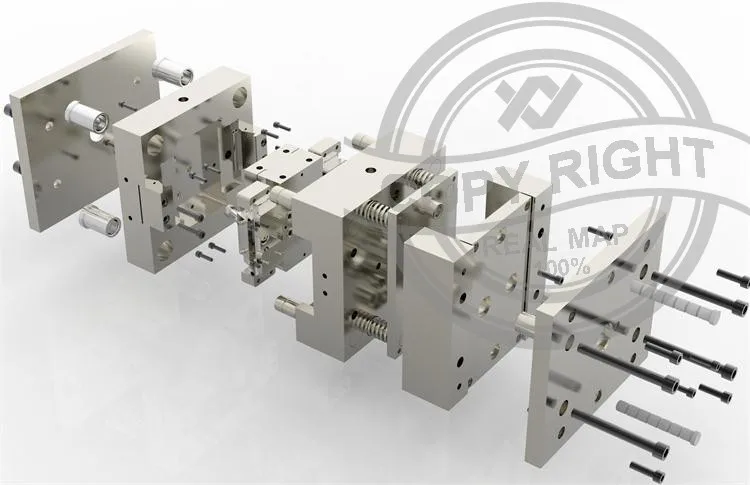

Mould material : NAK80 / S136

Mould base : LKM Mould Base

Surface treatment : Mirror Polish. Etched. Texture

Mould life : 250000-300000shots

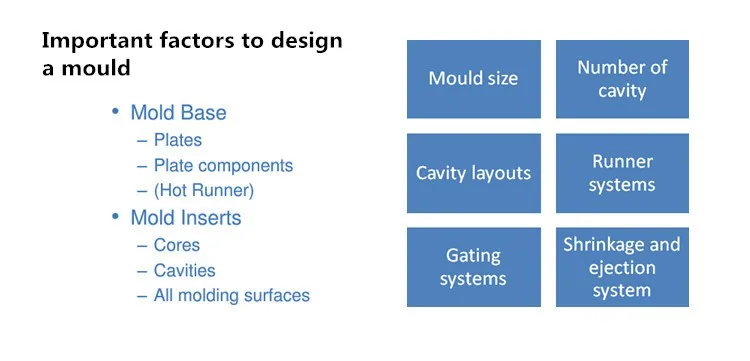

Runner : Hot Runner / Cold Runner

Design software : AutoCAD / UG

Cavity : Single Cavity / Multi Cavity

Injection Molding Material : PC / ABS / POM / PVC / PP ...

Name : Make Plastic Injection Mould

1. Grade: NAK80,S316,A2-70,A2-80,A4-80.

2. Size: Customized

3. Standard: GB,GJB,ISO,GJB9100B-2009

4. Certification: ISO9001, AS9100.

| Product Name | Plastic injection mould |

| Material | ABS, PC, PP, PS, POM, PMMA or Customized. |

| Color | Natural or Customized. |

| Standard | GB,GJB,ISO,GJB9100B-2009. |

| Application | Elevator, Auto, Motorcycle, Industry, Ariculture, Mine, Furniture, etc. |

| Working Process | Stamping, deep stamping, bending, punching, threading,welding, tapping, riveting. |

| Mould Base Material | LKM, FUTA, HASCO, DME, etc. or as per customer' s requirement. |

| Cavity Number | Single cavity, Multi Cavity, based on customer' s requirement. |

| Surface treatment | Powder coating, polishing, chrome plating. |

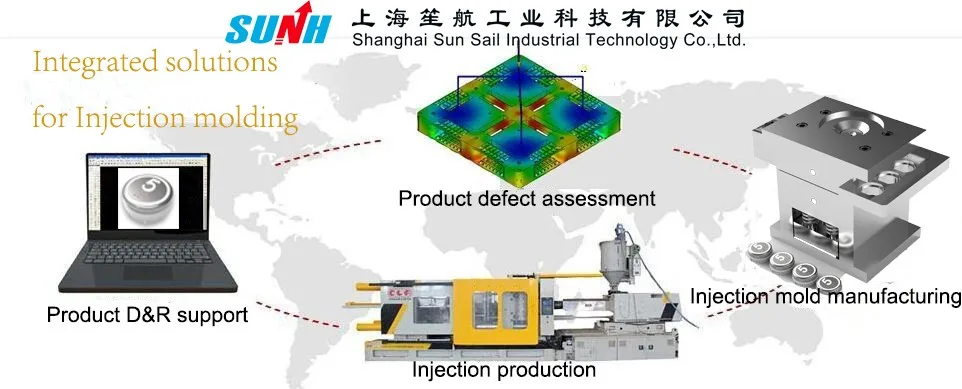

1. We are manufacturer, have 13 year OEM experiences, competitive price can be provided.

2. Rich experiences skillful designer and workers.

3. High quality plastic material and plastic mould material.

4. Strict quality Control.

5. Coordinate Custom's R&D program.

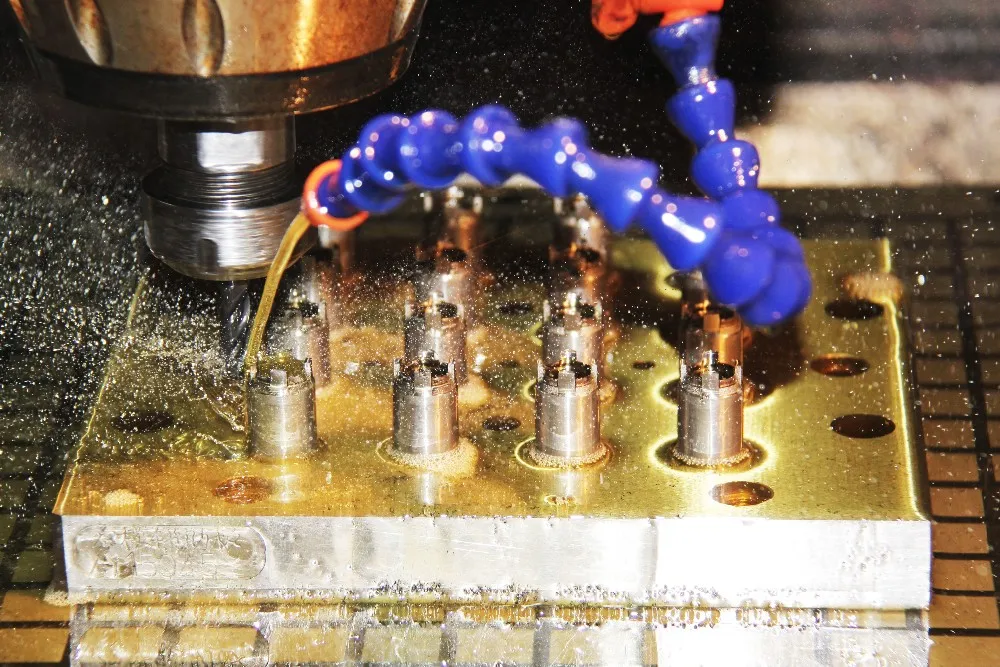

6. With high precision CNC, EDM, Wire-cutting, Grinder, Milling, injection machines,

we can supply you not only mould parts but also plastic products

1.We are a specilized plastic manufactory and design different plastic molds

2. Professional Elevator Plastic injection process

3.Different plastic materials,different colors,different shapes plastic injection products

4.If you have any new item need to be made,please contact with us.We can do our best to change your idea into real products.

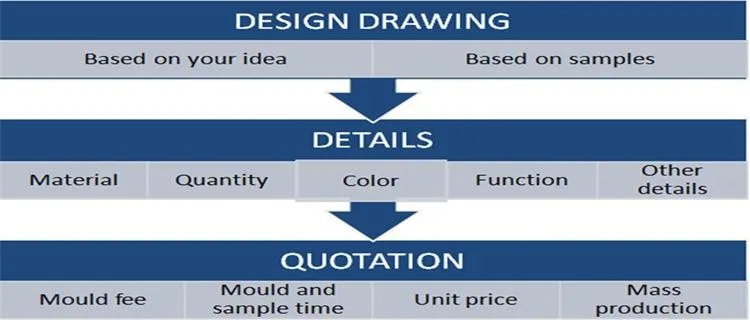

About the quotation,except the drawings both 2D and 3D drawing,the details just like which material you choose,what color you need,how many quantities need and so on are also very very important!

3.Making samples for you to check.if there is any parts need to change,we can revise the mold.

4.Mass production after samples approval and make the delivery.

Different tonnage of injection molding machine

Processing details

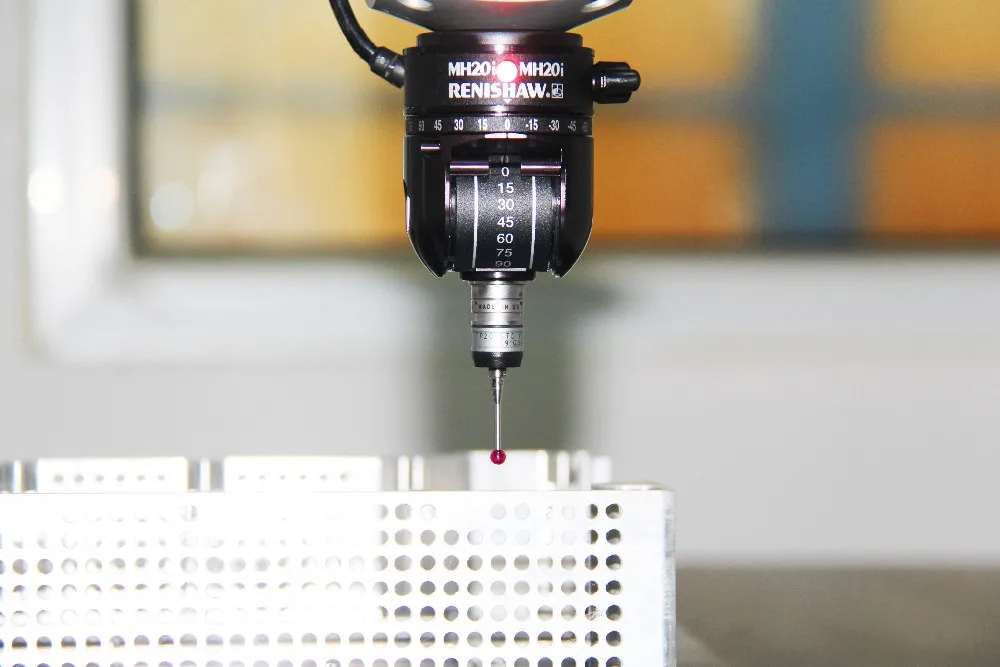

Precision EDM

Professional mold staff comfortable working environment

Specializing in elevator accessories product design, development and manufacturing

Used in product design, mold and equipment, gear measurement, blade measurement machinery manufacturing, fixture, steam mold parts, electrical and electronic precision measurement.

Second-dimensional image measuring instrument and professional inspectors

Packing Details : According to customer's requirements or conventional packaging

Delivery Details : 3-30 days after order

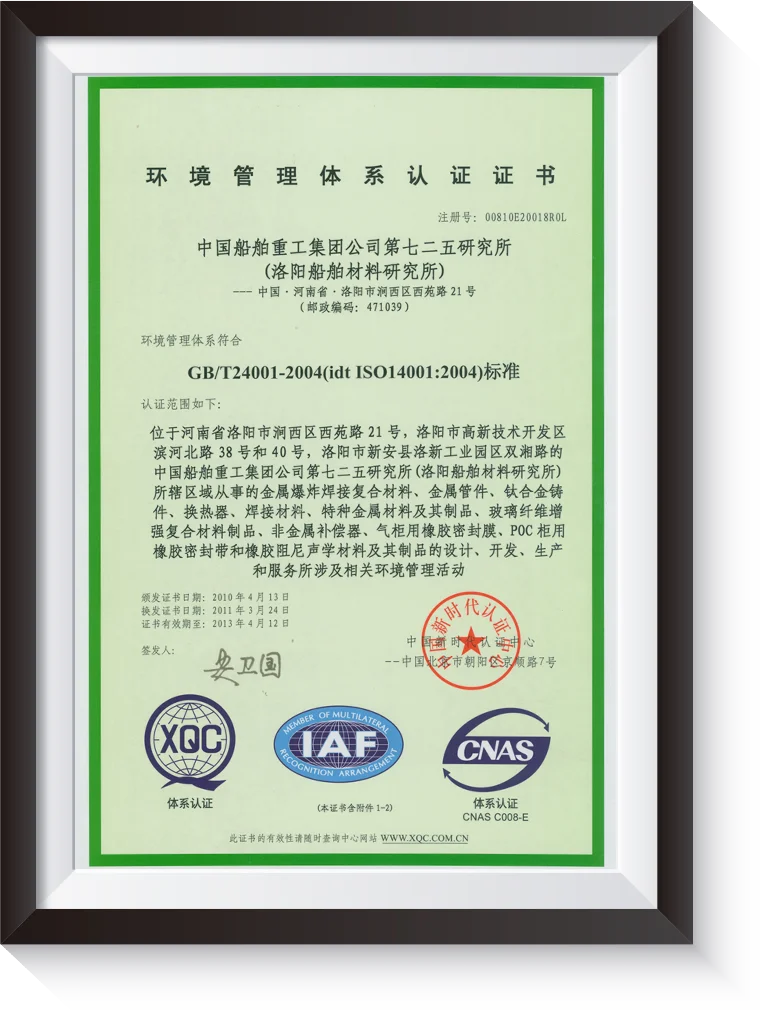

GB/T19001-2008/ISO9001:2008

BS EN ISO 9001:2009-2008

EN 9001:2009-2009

GB/T20041-2004(idt ISO14001:2004)

CHINA ALUMINUM ASSOCIATION

Semi-Automatic PET Bottle Blowing Machine

In the field of mold products patents

1.What can I get the quotation?

Within 12 hours the inquiry will be reply.If you are very urgent the price,

pls call us or tell us your email so that we will regard your inquiry priority.

2.How can i get a sample to check your quality?

Provide our existing sample to check our quality,the shipping cost need to paid by you.

After price confirmation,you can require for samples to check our quality,but sample cost need to paid by you.

The sample cost can be refundable if you bulk order quantity reach our request.

3.Can you do the design for us?

Yes.

We have a professional designing team,just tell us your details and we will help

to carry out your ideas into perfect products.it's also OK if you do not have the complete files. Sent us high resolution images,we can design the layout you want.

If you send your LOGO to us,we will make the artwork for you reference.

|

|

LKM Mould Base Custom Plastic Injection Molding For Elevator Parts Images |